Intro

Internet of Things (IoT) is making its move. In the beginning, it was something for the innovators and early adopters who like to play with new technologies. Today, IoT is something for the early majority who wants to improve the operational productivity with the latest technology. More and more organizations successfully evaluated business cases and cannot wait to get their Internet of Things (IoT) solutions running. It cannot be that hard — it’s the 21st century and the age of digitalization, so everything should be based on standards. You just cherry-pick your sensors, actuators, and an IoT platform, plug them together and go for it. Really? But why do almost 75% of all IoT projects fail [1]? Let’s have a look at typical pitfalls of rolling out IoT in organizations.

Dreaming of the nice IoT world

For many organizations the IoT journey starts with seeing a demonstration at an exhibition or reading about it in a magazine. A company, probably even in the same business, realized a great IoT use case. After some tinkering, they adopted it for their organization and showcased it in a shiny and visionary demonstration.

Impressed by this demonstration, your organization decides to start its first IoT project. An initial brainstorming brings up many use cases, some of them pass the business evaluation and a draft architecture and a list of requirements is quickly done. The management is impressed — by the innovative ideas as well as the estimated productivity gain. In the end, a budget for the first organization-wide IoT project is ready and the project team can start realizing the IoT vision.

A lot has changed since the first days of IoT and Industry 4.0, the IoT market became mature. Nowadays, there are plenty of hardware vendors for sensors and actuators and the prices dropped to an affordable level. The vendors have years of experience and offer a variety of field devices tailored to your individual needs. Moreover, there are numerous IoT platforms to connect your field devices with your IT. From big, notable companies who extended their portfolio with IoT, to smaller, more innovative companies dedicated to IoT. All have a bunch of features to fulfill the customers’ needs. And in comparison to years ago, the wild growth of protocols is over. MQTT and RESTful APIs became de facto standard to connect your IoT suite with your existing IT infrastructure. The same applies e.g. to OPC UA to connect IoT in production.

In comparison to the early days of IoT, things seem so easy now. You do not have to think about compatibility anymore, lose time with finding workarounds for your use case or work with a buggy beta-version of the software. Today, in the 21st century and the age of digitalization, it looks like you just cherry-pick the things you need, plug them together, and voilà: your business is IoT-enabled…

The pitfalls of IoT

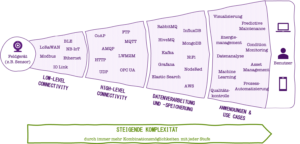

…at least this is what some homepages, magazines, and consultants make you think, or what you expect it to be. But the reality is different: the devil is in the detail. Studies figured out that underestimated complexity and a lack of IoT expertise are among the top 5 reasons for failing IoT projects [1] [2]. If you once set up an IoT infrastructure, you know about the complexity of IoT and the difficulties it can cause if you choose the wrong tools and setup. Let’s have a look at some examples to be more concrete:

The first pitfalls already appear when you choose the basic technology and the common communication protocol. It is the decision which data highway your organization uses to connect everything, and it is a crucial decision. For a real highway, you have to decide where it leads, how big it is, and how good the streets should be. Likewise, for the data highway in IoT you have to select the devices and IT-systems you want to connect, the maximum bandwidth, and how resilient the connection should be (see also [3]). This decision depends very much on your environment and IoT use cases, which are usually not that well-defined and might change at this early stage of your IoT project. Besides, it is the first IoT project for your organization — so there are many blind spots and missing IoT experience. A common mistake is to go with the cheapest solution, which turns out to be less flexible, with a high vendor-login, or not capable of big roll-outs later.

The decision for the right data highway depends on several questions, e.g.:

- Do you have sensitive IoT data and/ or want to be flexible with the infrastructure? In this case maybe setting up your own IoT infrastructure (e.g. with LoRaWAN) might be right for you. Or do you want to outsource the infrastructure and need connectivity almost everywhere? Then maybe NB-IoT or 5G is the right technology for you.

- Do you know where you need connectivity? Is it just needed in your office building or do you have spots where it is hard to provide coverage, like basements or production facilities? Do you need city-wide/ country-wide/ world-wide connectivity, e.g. for use cases related to supply-chain-management and logistics?

- Do you need to transfer big amounts of data between your field devices and the IoT platform? “Big amount of data” can be caused by many sensors (e.g. for monitoring conditions in many rooms), short sending intervals (e.g. in fast-running production machines), or much data that need to be transferred (e.g. video streams from cameras).

As you can see, there are many questions to answer. And sometimes their solutions are even contradictory. E.g. a mobile connection for a country-wide access to your data conflicts with good coverage in basements. Or portable surveillance cameras, which have high power consumption for recording and transferring the video but require to be battery-powered. The more use cases you realize, the more you will suffer from a bad data highway!

After the decision for a data highway, the next pitfalls wait for you when it comes to selecting the right field devices for your use cases. Here, the challenges are choosing the right devices for your use case as well as choosing a reliable vendor with good support.

Usually it is obvious which kind of sensors you need to measure the right physical properties. E.g. if you want to know the conditions in rooms, you take a temperature and humidity sensor. But it is getting more complicated if you cannot directly measure the physical property and thus have to find an alternative. E.g. in production, if you want to quality check whether the assembly installed all parts. A visual control requires complex object recognition techniques and the possibility to “see” into the product. As an alternative you measure the weight and by this calculate whether a product is complete or not. Similar problems appear if you have strong and changing influences from your environment. Changing outside temperature or changing daylight can make it hard to get reliable data from your sensors. And in some cases you need to project properties because you cannot directly measure them, e.g. inside a curing oven. These simple, but prevalent examples can quickly ruin your use case if you do not find a reasonable workaround.

As soon as you identified the types of sensors and actuators you need, you can start searching for concrete products and vendors. Now, the pitfall is to find the right balance of price and quality. Typical things to check are:

- Does the device satisfy your requirements? E.g. is it suitable for working outdoors and operating in your temperature ranges? Is it resistant to water, dust, shocks etc.? Is the battery runtime sufficient for your use case? Running a sensor in the wrong environmental conditions means a shorter lifetime and/ or wrong data measured.

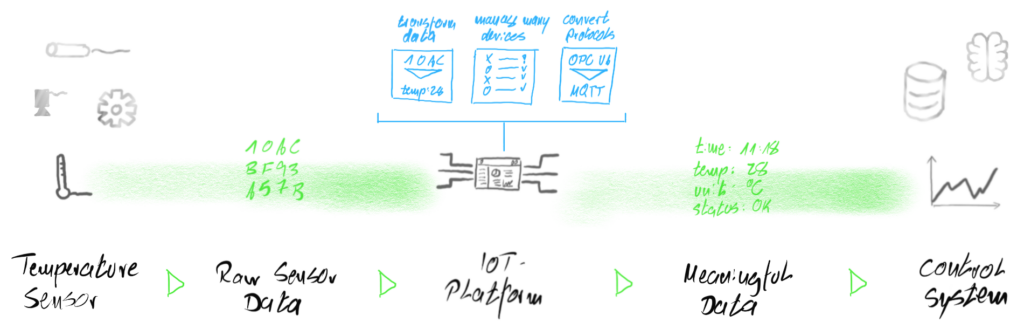

- How easily can the sensors and actuators be configured and integrated? Usually, you have to parameterize and calibrate each field device. For this, your engineers need clear instructions from the vendor on how to do this. Besides, devices often send raw data packages that need to be converted. If you do not get a parser or at least a description of the data package payload, it will be tough to interpret it.

- Can the vendor keep promises made in the technical data sheet and do they offer support for the configuration as well as in case of breakdowns? Some manufacturers designed their products at the cutting edge and hardly can keep the promises given in the technical data sheets or they have a high variety among their products. A sudden breakdown or much shorter lifetime of the field device means high maintenance costs later.

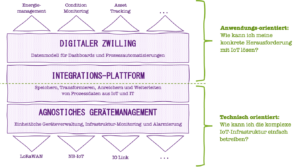

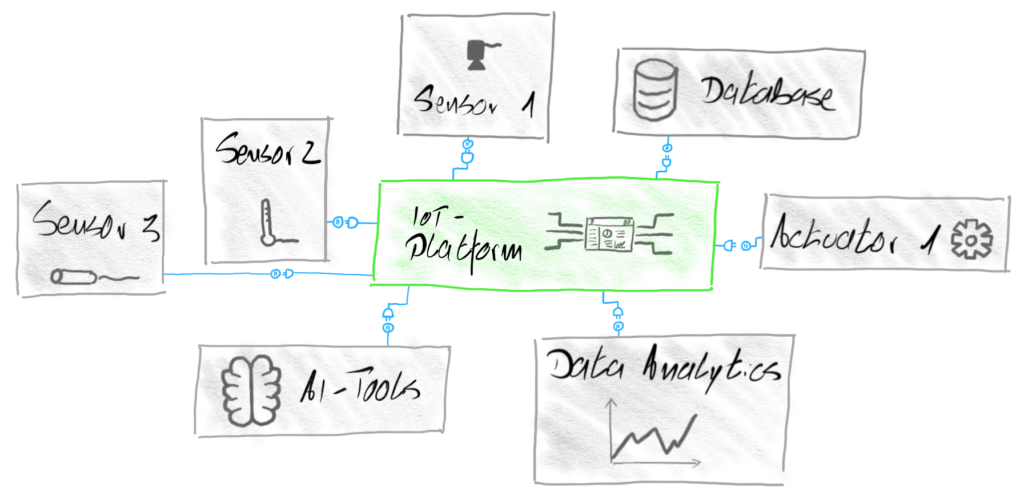

Now that you know the pitfalls in the physical world of IoT, we can switch to the digital world. Your IoT platform will play a crucial role in your IoT implementation. It will connect all sensors, actuators, and IT-systems in one place. Besides, it converts different protocols and standards and will be the place to monitor your infrastructure and store raw data for data analytics.

Thus, an IoT platform is more than the glue to stick everything together!

It is important to choose this piece of software wisely:

- Does your IoT platform provide parsers etc. to quickly integrate new sensors and actuators? Some “smart” field devices can deliver meaningful data, e.g. when they are pre-processed by an edge device. But many field devices only deliver and receive raw data (like LoRa devices do). In this case, your IoT platform needs to parse cryptic data from devices into meaningful data. Writing such a parser can be very easy, but is often very frustrating. Especially if you get bad technical documentation of the device and little to no customer support.

- Can the IoT platform be integrated into your IT environment? Most IoT platforms support common standards like MQTT or a JSON-based REST API. There are standards used only in certain domains (like OPC UA, MTConnect). But you do not know which standards and IT-systems will pop up in the future. So if your IoT platform is not extendable and has limited long-term-support, you will have to re-think your whole IoT infrastructure in the future. Do not underestimate the integration — almost 30% of all companies using IoT suffer from a false estimation of complexity [4].

- How does your IoT platform support your IoT rollout? Companies often start with a small PoC including a lot of manual work. They evaluate technical feasibility and business impact, but forget to check how the IoT platform supports rollouts. Adding 10 devices and manually writing parsers for a PoC is fine, but if you need to do it 10.000 times for a rollout, it is almost impossible without proper features like bulk-editing or templating. Also, monitoring the conditions for 10 devices is easy. But monitoring 10.000 devices means you need automated checks. E.g. alerting in case the battery is low or a field device lost its connection.

- How can your IoT infrastructure support your business processes? Connecting an IoT platform with IT-systems is one thing. But where is the data transferred? Are there any features to trigger workflows, group business information in one place, represent non-IoT-objects like machines, buildings, etc.? To really benefit from IoT, you shouldn’t see IoT as a separate part of your organization, but fully integrate it.

Innovators and early adopters, like the company with the shiny demonstration from the exhibition, usually are very tech-oriented. They have electrical and computer science engineers to solve technical challenges, and their project managers know how to take these risks into account. In addition, they know that projects with early technologies might fail.

But other organizations, which are in the role of an early follower, have different prerequisites: they expect a short-term measurable impact of the new technology, but did not gather the necessary knowledge yet. In the end, the vision of IoT, which other organizations successfully realized, quickly starts to stumble. The proof of concept (PoC) never goes live. IoT will be yet another technology that caused more frustration than benefits. Being aware of all these before mentioned pitfalls and the devil in the detail, what can organizations do to avoid these pitfalls?

Some hints to beat the devil

You noticed it yourself: the root of all evil is a lack of experience with IoT [1]. This is nothing unusual — IoT is in comparison to other technologies pretty young and thus little companies have years of experience. But if you are aware that you cannot foresee every pitfall and that you do not know all use cases, and thus IoT’s full potential is unknown yet, you can try to prepare for the uncertainty.

1st, do not save on the IoT hardware and software. As mentioned before, with cost-saving sensors and actuators it might be that they have little fault-tolerance or even cannot keep the promises from the technical sheets. Of course, there are hidden champions that are reasonable and provide high quality — you just need to know which one. The same applies to the IoT platform you choose. Immature IoT platforms have a certain risk as their platform is not as battle-proven as others. “Mature” in this case does not mean a company with a big name — some of their IoT departments are quite young as well. It means a company that focusses on IoT, has relevant references and their experts can give you an objective evaluation on feasibility. Low-budget solutions are often missing crucial features to support IoT administrators. E.g. features like pre-defined parsers, managing bigger amounts of devices, monitoring the IoT infrastructure, and recommendations for good IoT sensors and actuators are valuable for the engineers who have to rollout IoT. Furthermore, good IoT platforms offer extended support and possibilities for customization beside a long-term availability of updates and new features. Like with the experts, higher costs will result in fewer efforts for maintenance and customization and a resilient IoT infrastructure.

2nd, get support from IoT experts to fasten up your project and learning curve [1]. The Mona Lisa needed several tries and re-paintings to become that perfect. Likewise, your IoT team will waste some of the budgets to find the right IoT solution for your organization. Especially when it comes to choosing the right data highway or field devices, taking independent expertise into account is valuable. The wrong data highway will bring you limitations (so-called “technical debts”) that affect all parts of IoT every day and thus have a huge impact. For field devices, without knowledge of good products you need to test and figure out yourself whether this IoT device is the right and reliable one for your use case. Experts have this knowledge, can give you early feedback on technical designs, and bring in additional use cases. They have hands-on-experience and made all the beginner mistakes already before, so they know how to avoid them. The costs will give a good return as they shorten the project runtime, avoid sunk costs, and add new IoT use cases to realize further benefits.

3rd, you need to take an agile project management approach. Do not try to plan everything in advance and be aware that setbacks will appear. Give the project team a clear business objective (e.g. “reduce downtime of machines by 60 min. with IoT”) and let them find a way to realize it. Do regular reviews in short intervals, even in the early stages of the project when the team is happy to get the IoT devices running. By this, your organization will share the IoT knowledge and you can give early feedback. Start with a small PoC that is running in your daily business environment to become concrete enough, but is isolated so that it does not harm your operations. If it works, scale it up by rolling it out to other areas. Besides, do not think IoT is a single project — it is a series of many use cases. Thus, do not limit your budget to only one project. With the first project the team will bring up many more beneficial use cases and ideas. The more use cases you realize, the more the investments into your IoT infrastructure will leverage (see also [6]).

A lot of things to consider — maybe if IoT is that complicated, it is better to skip this topic? Well, this seems to be a bad idea — there is a great potential of IoT and it will be one of the enabling technologies of digitalization in many organizations. Besides, almost all companies implementing IoT are convinced of its benefits. More than two-third realized a return on investment in less than a year [5]. Even among companies which IoT projects failed, more than 80% have been convinced of the potential. So skipping the internet of things means bringing other problems on the table…

TL;DR (aka “summary”)

IoT projects are different from other projects. Problems from the physical world like environmental influences and hardware quality merge with problems from the digital world, like data management and connectivity. In the last years, IoT left its infancy: field devices as well as IoT platforms became mature and are now ready for big rollouts and usage in operations. Nevertheless, IoT is not (yet) at the point where you just plug ’n’ play everything and that’s it. Do not underestimate the tiny problems that will for sure occur and the blind spots of knowledge in your team which will let you oversee critical aspects.

However, to make IoT successful in your organization, involve employees or partners with hands-on IoT expertise covering field devices, data engineering, and IT infrastructure knowledge. Take an agile approach which makes your project more flexible so that you can adapt to future insights. Do not just focus on short-term success and the project budget. Think big and about the long term so that the investments into your IoT can pay off by implementing further use cases later.

Like in many other areas of life, do not go for the cheapest solution — you will pay twice for maintenance and missing possibilities to adapt to your needs later. Instead, take the path with the greatest expertise and that offers battle-proven solutions to your engineers. Besides, look for the solution which keeps your flexibility and can guarantee long-term support as many future business processes will rely on your IoT infrastructure.

Sources & further reading

[1] CISCO — The Journey to IoT Value (2017)

[2] Microsoft — IoT Signals: Summary of Research Learning (2019)

[3] D. Kolberg, M. Göke — Die Digitale Datenautobahn: Rückgrat der Digitalisierung (2019)

[4] Ubuntu (2017) — Defining IoT Business Models (2017)

[5] Computerwoche — Internet of Things 2019 (2019)

[6] D. Kolberg — IIoT: Do we really need IoT platforms in production? (2020)