Intro

Today, the Internet of Things (IoT) has left its infancy. It has become one of the core technologies for the age of digitalization. With this transition, IoT has to address new requirements. Rollouts into business operations suddenly require professional integrations into existing IT-landscapes and easy-to-use applications. The Digital Twin is a rather young concept. It describes the virtual representation of physical business objects. On the first glimpse, combining IoT and Digital Twins seems promising. But why and how can both together pave the way for the future of IoT?

Today’s challenges of IoT in rollouts

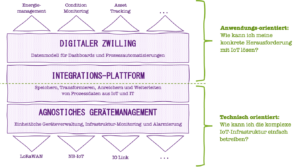

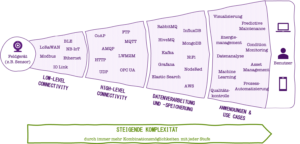

In the past, one of the biggest challenges for IoT was its immaturity. There have been few products for professional applications and a lack of skilled employees. Certainly, IoT-pioneers remember the days where they had to work with semi-professional IoT-devices and self-written code to implement simple use cases. But nowadays, things have changed. A bunch of time-tested IoT-devices is available to realize whatever use case comes into mind. Besides, IoT-platforms provide all necessary features for operating professional IoT-environments. From managing thousands of IoT devices to the support of various protocols, IoT-administrators find everything they need.

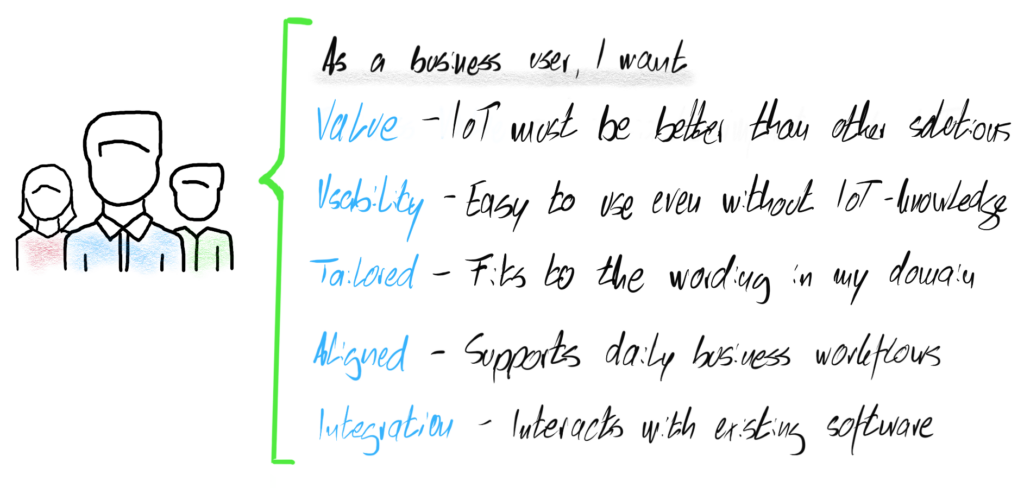

Surprisingly, more than 75% of all proof-of-concept projects in the IoT-world fail nowadays [1] [2]. Reasons are — beside others — the new requirements arising from business operations. With the transition from a proof-of-concept into an organization-wide rollout, a new group of users needs to work with IoT: business users. They are usually less interested in technology and do not have any IoT-expertise. Business users want to improve their operations and have a wish for an easy-to-use system. Or in other words:

The business users don’t want to know what IoT is — they want to get their problems solved no matter what technology is used!

As a consequence, IoT-platforms have to adopt three aspects because of this new group of users. First, user interfaces that are easy to use even for IT-inexperienced users are required. Second, IoT-platforms need to provide solutions that are tailored to certain business processes to avoid being too superficial for concrete business needs. And third, besides integrating IoT-protocols and ways to push data to IT-systems, IoT-platforms also need to implement various domain-specific protocols to receive data. This is necessary because business processes are not IoT-focused, but need to proceed data from various sources.

But if so many IoT-projects fail so early, maybe IoT is not as outstanding as we think? Although we are still stumbling with bringing IoT into a rollout, more than 80% are convinced that IoT paves the way for digitalization in their organization [3]. IoT is the core technology to bridge the IT-world with the real world. Sensors deliver the process data consumed by IT-systems and actuators are the way for IT-systems to interact with the real world. So it is not about wether IoT is bringing value to organizations, but more about what is missing to fulfill business user’s needs. The answer to this question will foster IoT’s transition from proof-of-concept into rollout.

Digital Twin — the new kid in the hood

Although the Digital Twin seems to be a rather young concept, it is known since the beginning of the 21st-century [4]. A Digital Twin is a virtual representation of a physical object, storing all its information throughout its lifetime. Or in short: it is an avatar of something real. Originally, they have been invented at NASA for systems and product engineering. For example, at NASA, they could save time and money by using Digital Twins for material simulations instead of tests on real objects. Besides, a Digital Twin can also be the single source of truth for the current as well as past state of a real object.

Digital Twins are pretty abstract and hard to understand. So let’s have another example: To some extend, your social media profile is a Digital Twin of yourself. It saves your master data (such as hometown, date of birth, name, etc.) as well as your process data (like updates you post, places you visit, images you upload, etc.). Besides, you can add links to other sources (e.g. your homepage or LinkedIn profile). To sum it up, your social media profile is a digital avatar of yourself. It saves all information about yourself in one place, which can e.g. be used in online marketing to predict your interests.

n practice, Digital Twins are used for example in constructions. During the planning and construction of a new production plant, many departments need to work together. They are all working on the same object (the building itself), but with different information needs:

- Architects are interested in the model of the building — and will most likely update this part of it.

- Engineers need to know material properties and detailed plans of pipes and wires — and will most likely update only this aspect of the Digital Twin.

- And the production planning department is only interested in the arrangement of machines and material flows — and will most likely only update this part.

With building information modeling (BIM), a method for Digital Twins tailored to the needs in facility management, and AutomationML, a protocol for exchanging plant engineering information, there are already concrete approaches for Digital Twins for this use case.

As you can see from these examples, there are different types of Digital Twins depending on the product life cycle phase. A so-called Digital Twin prototype is mostly used in engineering. It represents a type of product that does not necessarily exist yet. With the Digital Twin prototype, engineers can simulate behaviors like material performances or interference checks. Also, they have all information for engineering in one place, like the bill of material and CAD drawings. Instead, the Digital Twin instances are used during the runtime of a product. They represent a concrete existing object and are linked to its lifetime. It saves the history and current state of this object. With the Digital Twin instance, users can e.g. see when components have been maintained and when this product was used. Besides, they can remotely see the current state of the real object through the Digital Twin. [4]

Today, Digital Twins are getting more and more attention [5] [6]. Business users are expecting a higher efficiency, better satisfaction of customer needs, and maybe even new types of products. So it is no surprise that many companies are expecting a high impact and are already working with Digital Twins. [7] But — besides these studies — what is the reason that the Digital Twin is so appealing to non-IT departments? The Digital Twin is (one of) the first approaches which links data from various sources in one place. But in comparison to other approaches, the data is grouped from the point of view of a business department rather than a tech-department. Digital Twins are not a new middleware or any other concrete technology, but more a concept of how to process data. This leads to better support for business processes due to less media discontinuity, less search time, and new applications with business value like real-time simulations.

IoT + Digital Twins = new love?

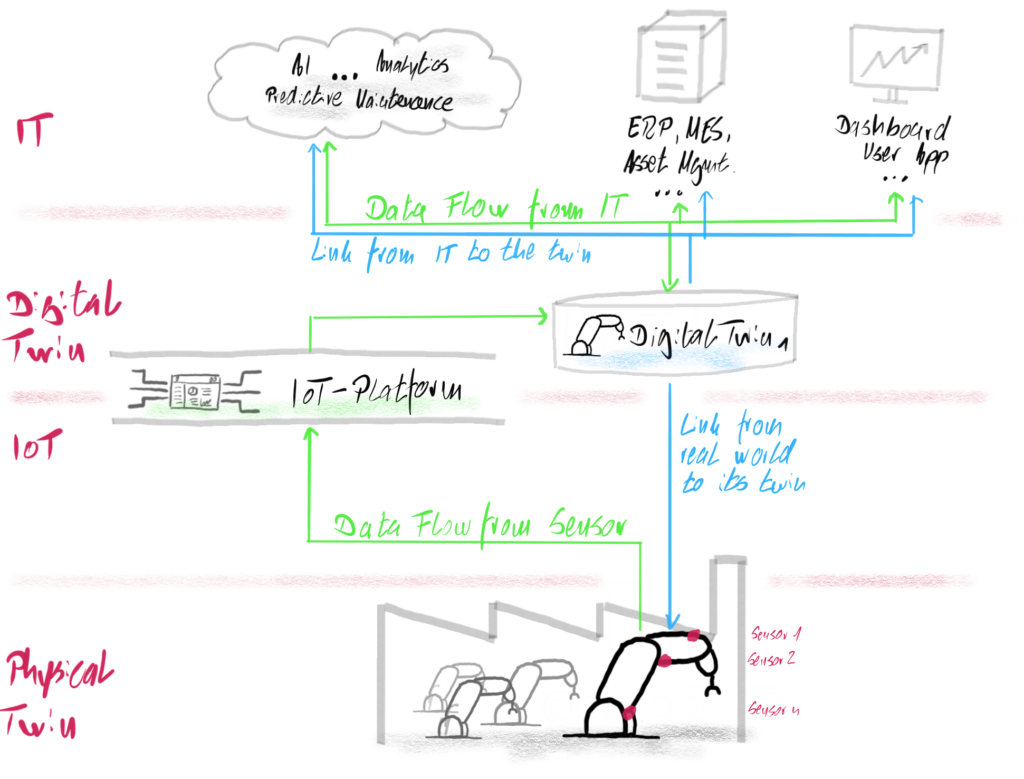

In some respects, a Digital Twin is a connector between the tech and business worlds. And therein lies the opportunity for IoT. With the transition from proof-of-concept to a comprehensive rollout, IoT needs to address the needs of business users as well. Business users are experts in their domain, but usually have little experience and interest in IoT. They want an easy to use solution, perfectly tailored to their daily needs. The Digital Twin is capable of linking all IoT and non-IoT data in one point, organized by the point of view of business users. Thereby, business users are finally able to use the power of IoT even without knowing that ‘IoT is running under the hood’. Besides, IoT data can be enriched by information from any other source, e.g. master data from ERP systems.

Let’s have an example: With Digital Twins, you can represent your production plant as a whole. You can have Digital Twins for each building, line section, machine, etc. All IoT-sensors of machines, forklifts, and so on are linked to their corresponding Digital Twin and deliver information such as temperature, speed, and position in real-time. Through direct connections to the third-party systems, each Digital Twin is enriched by e.g. maintenance plans, work order queue, cost center, etc. The Digital Twins can use this information to plan maintenance slots, precisely calculate the completion time of tasks, or provide key performance indicators such as its utilization. The foreman has all the required information in one place — without having to think about from which source the information is coming.

IoT benefits from the Digital Twin — but the Digital Twin benefits from IoT as well [8]! Without IoT, a Digital Twin would just be a collection of static data. This is nothing new — most IT-systems like ERP-systems or asset management solutions provide similar functionality. IoT delivers information about the physical condition in real-time to turn a Digital Twin into an alive avatar of the physical object.

Only the fusion of IoT and Digital Twins makes the Digitalization broadly accessible for non-tech users

Furthermore, having all information accessible in one place fastens up the engineering and integration of further digital solutions and interaction with other software systems.

TL;DR (aka “summary”)

IoT is at a turning point: after years where pioneers evaluated the potential of the new technology through proof-of-concept projects, IoT is now mature enough for comprehensive rollouts. But with this step, many new requirements occur. Business users need an easy to use system tailored to their daily processes to realize measurable value with IoT. Besides, IoT data must now be combined with additional meta-information from other IT-systems.

The Digital Twin is a rather young approach to represent business objects as digital avatars. In comparison to other approaches which collect all information in one place as well, the Digital Twin aims for real-time synchronization with the real world. By using IoT, the Digital Twin becomes alive and provides the usability needed for business users. Having process data as well as metadata in one place will furthermore pave the way for ‘real’ artificial intelligence in the future. But this is something for another article…

Sources & further reading

[1] [CISCO — The Journey to IoT Value (2017)]

[2] [Microsoft — IoT Signals: Summary of Research Learning (2019)]

[3] [Computerwoche — Internet of Things 2019 (2019)]

[5] [Google Trends — Search inquiries of the past 5 years for ‘Digital Twin’]

[7] [U. Weber, H. Grosser et al. — Digitale Zwillinge: Wegereiter für Ökosysteme von morgen (2019)]

[8] M. Eigner, A. Detzner, P. H. Schmidt, R. Tharma — Definition des Digital Twin im Produktlebenszyklus (2019)